Check out what's been happening at Monkeytoe in April in our latest monthly news feature.

A note from Budd

We’ve been busy in head office. Despite some restrictions, thankfully it’s largely been business as usual. We’ve shifted a lot of operations online and have offered no less than 40 virtual presentations on our products this month. We also anticipate more to come, so to keep things moving forward you will find a pop over on the homepage that will allow you to book a virtual product presentation directly.

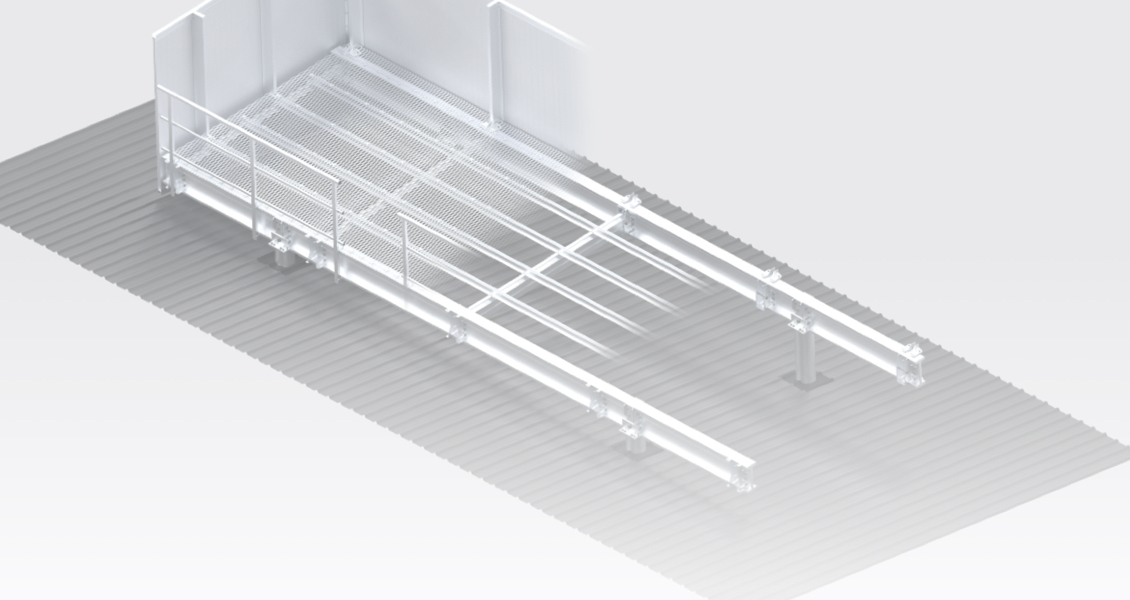

Speaking of technology, in this newsletter we had our Development Manager Logan Klenner answer some of your FAQs on our recently launched Xbeam. From waterproofing to carbon fibre incorporation, there’s a lot here to consider. There’s also the opportunity to download our ebook “Bigger, Taller, Stronger” to learn more about the technology behind the carbon fibre components on the Xbeam.

But first, some important updates as to how we’re doing our part to minimise the impact of COVID-19.

All the best,

Budd Prestidge, General Manager

COVID-19 Level 3

New Zealand has done a fantastic job of minimising the spread of COVID-19, but there’s still a way to go yet. As of the 28th of April, we’re now in level 3, and taking the first tentative steps towards resuming operations.

As well as following the official health advice, we’ve instructed our teams on the procedures and protocols to ensure that our collective health and livelihoods are secure, including preventing likely or confirmed cases from being allowed on site or in offices or workshops. We’re also enforcing strict physical distancing and hygiene standards, doubling down on PPE and cleaning regimes, and staggering breaks, among other procedures.

We appreciate all our team members, associates and clients who are helping us all stay safe and healthy. Together we can beat the curve.

FAQs with Logan Klenner, Monkeytoe’s Development Manager

Since the Xbeam is such a new and innovative product, we put together a list of questions that have cropped up and sent them to our Development Manager, Logan, to answer.

1) Do you also take care of the waterproofing detail of the roof penetration?

Monkeytoe supplies the appropriately sized Dektite boot with our Stub leg kits, which should be installed by the main roofing contractor at the time of roof install. This typically means that the leg stubs are installed before the roof itself. On a retrofit project, if there is an existing roofing contractor then we recommend they be engaged to install the boots.

If there are no roofers currently on the job then Monkeytoe can engage one for you.

2) Do the penetrations through the roof require a flashing detail?

This will depend on the roofing type being used on the building. The standard manufacturer’s flashing detail should be used for a Ø250 round penetration using a Dektite boot. Backtray flashings may be required for some profiles and not for others.

3) Is the Xbeam a watertight unit?

The beam is manufactured as a sealed unit, however some penetrations are made for connection to the beam. Where required, these can be sealed using neoprene washers or an appropriate silicone sealant.

4) Are there any concerns about dissimilar metals at hub portal connections, such as between zinc bolts, aluminium structures and steel beams? Are there any risks of galvanic corrosion?

In short, no. Where these connections are made inside a building, there are no concerns. For galvanic corrosion to occur, an electrolyte must be present to complete the electrical circuit. This should not be happening inside a building often enough for corrosion to happen. As an added precaution, however, Monkeytoe recommend using a lanolin moisture/corrosion inhibitor spray at the time of install to prevent any moisture from being trapped during construction.

We have chosen zinc bolts for this application as they are more compatible with aluminium than galvanised fasteners are, and they maintain compatibility with the steel structure. Where this connection occurs in a weather-exposed area, isolation will be provided between all dissimilar metals to mitigate and prevent corrosion. This will typically be a thin rubber or hard plastic layer, but in some situations a specialised coating may be used.

5) Does Monkeytoe engineer and certify from portal up?

Monkeytoe will engineer from our connection point upwards, including the fasteners used. If we are providing the leg stubs, then this will be from the portal up (but not the portal itself). If we are mounting to support legs that are supplied by others, our engineering will cover from our connection upwards. Monkeytoe can assist with the design requirements for the legs in this case.

6) Monkeytoe’s aluminium is designed to AS/NZS1164 (Aluminium structures). How is carbon fibre covered?

This is covered by a combination of physical testing as per AS/NZ 1170.0 Appendix B, as well as reference to the European composites code where applicable.

7) Where and how is carbon fibre incorporated into the Xbeam?

Carbon fibre is fixed into the top and bottom flange cavity of the beams in the form of ‘Spar Caps’ by use of a structural acrylic adhesive.

8) What glues or adhesive are used to fix extrusions together, and what testing have these undergone?

We started with over 50 different potential options and narrowed these down over a period of more than six months, with various tests and discussions with adhesive chemists. We conducted hundreds of lap shear tests at temperatures ranging from below ambient to up to +200°C in order to select our adhesives. The aluminium-aluminium bonding is achieved with a high temperature capable adhesive that has been specially formulated for us by Bondchem in the UK. The carbon fibre-aluminium bonding is done with a Bondchem structural acrylic. We also have other equivalent options that have been tested and that can be substituted if needed.

In other news

Our latest ebook, “Bigger, Taller, Stronger: Realising the potential of carbon fibre” is available for download from our website.

The real advantages of carbon fibre reinforced plastics are in how it combines the relative strength of the carbon fibres with the durable matrix of resins to create a product that’s greater than the sum of its parts. Little wonder that it’s used in aerospace, high fashion and, most recently, together with aluminium in our Xbeam range.

Download the ebook and find out more about this versatile material that’s expanding the scope for what’s possible in design and engineering.

We’ve made a short video to showcase and celebrate what we do and the people that make it possible. Consider it an ‘intro to Monkeytoe’ video – covering the scope of design, manufacture and install solutions we offer. Check it out here: