There are a myriad of ways to isolate unwanted vibration. In the past, vibration could be minimised by using cork or felt pads under equipment. Increasingly powerful auxiliary equipment like air conditioning units and power generators are now needed, however, and are often installed on upper levels of plant rooms or rooves. Equipment vibration can be a major issue on flexible structures in a way that cork and felt are unable to handle.

Nowadays there is a wide range of vibration isolators to choose from, including pads of cork or rubber, spring mounts, air mounts, isolation hangers and even seismic mounts. From the smallest pipes, even up to the ‘base isolators’ supporting the Museum of New Zealand – Te Papa Tongarewa in shaky Wellington, they’re all designed with the same goal in mind: reduce vibration transmission. As we’ve seen, determining the viability of an isolator depends on the nature of the vibration and the environment where it is to be used. It also hinges on the type of isolator that can be used, and what sort of properties each type has which may make it more or less suited to each environment.

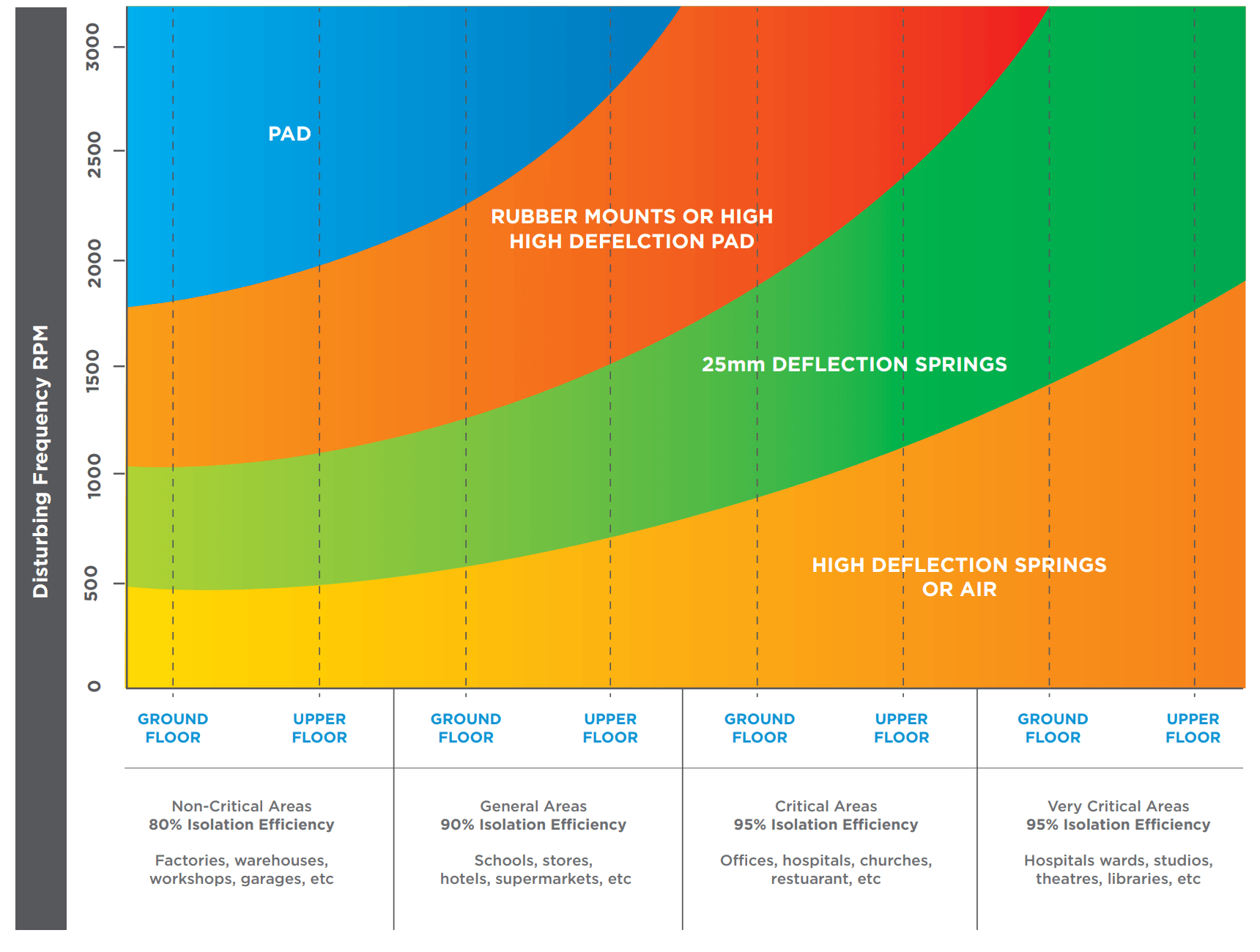

The below graph provides a good guide to acceptable isolator solutions depending on disturbing frequencies and the environments.

Let’s look at these common types in turn and see what solutions they offer.

PAD MOUNTS

Pad mounts are low-cost – often under half the price of spring isolators – and can be made of rubber, cork or felt, or a combination of these sandwiched together. Pad mounts are ideal for situations including:

- Common disturbing frequencies in the order of 1,000-2,200 RPM.

- Loads in the order of 75-750 kilopascals (kPa, equivalent to 1000 kg per square metre).

- Static deflections arereasonably narrow (a few millimetres).

Pad mounts are an effective low-cost option with a reasonable degree of isolation efficiency that tends to improve with greater disturbing frequencies. They are generally used for standard, non-critical applications including pumps and fans, generator sets, general industrial equipment, mobile equipment, electrical transformers and packaged air.

SPRING MOUNTS

Spring mounts have great static deflection, making them great for a wide range of isolation applications. Since springs can be scaled in size, they suit a wide range of critical applications including fans, pumps, air conditioning units, engines, cooling towers and even heavy machinery. Springs represent a wide band of applications, including for:

- Disturbing frequencies from 50-5000 RPM, according to load and location.

- Loads in the order of 6-11,000 kg, depending on type.

- Static deflections from 15-100mm.

Spring mounts may be open, or have a housing that restricts lateral (side-to-side) deflection, and often have rubber pads built into the mount to further reduce vibration transmission. They can help achieve a theoretical isolation efficiency up to 99% depending on the spring type and application.

Steel spring mounts provide effective isolation from mechanical vibration, however the spring itself has its own inherent surge frequency depending on its physical geometry and material properties.

AIR MOUNTS

Quality air mounts are made from a balloon of low permeability rubber sandwiched between plates (usually steel). They offer the highest efficiencies as they isolate the vibrating unit on a cushion of air, so they’re often found in extremely critical applications in hospitals, research laboratories, and music auditoriums, or with:

- Disturbing frequencies typically around

1-5 RPM with high frequency peaks. - Loads in the order of 10-4,500 kg,

depending on type, and - Static deflections from 15-100mm

Air mounts are great for shock absorption – you’ll often find them in the transport industry where high loads are handled in small spaces like in trucks or trailers. They’re also quite cheap in relative terms, however the constant dynamic load and nature of rubber and air leaks means they’ll require a mechanical plant or maintenance cycle to ensure the pressure is maintained. This will need to be factored in when compared to the low-maintenance nature of springs or pads.

ISOLATION HANGERS

Isolation hangers are often the same spring mounts as before, but inverted and with a longer stud to fix it to the structures from above. Isolation hangers are used for piping, ductwork, fans, suspended ceilings, attenuators and other applications where it’s necessary to isolate by hanging – as their name suggests. They’re a critical part of the overall design, as piping and ductwork often connect directly to the source of vibration. Given they are of a similar nature as other spring mounts, they have similar features but lower weight tolerances, so are suitable for:

- Disturbing frequencies over 500 RPM.

- Loads in the order of 5-1,300 kg,

depending on type. - And static deflections from 5-55mm.

Isolation hangers may also be used as part of a thermal expansion control system, supporting piping where thermal variations can impose considerable vertical movement such as in the risers of multi-storey buildings.

Once you’ve determined your loads and the quality of your vibration, you’ll be able to see what kind of isolator will be best suited and choose one from a catalogue according to your range.

Unfortunately, vibration is often overlooked or oversimplified, even by some of the greatest architects and engineers. Download the ebook to make sure you’re prepared for vibrations in any form they come.