Close

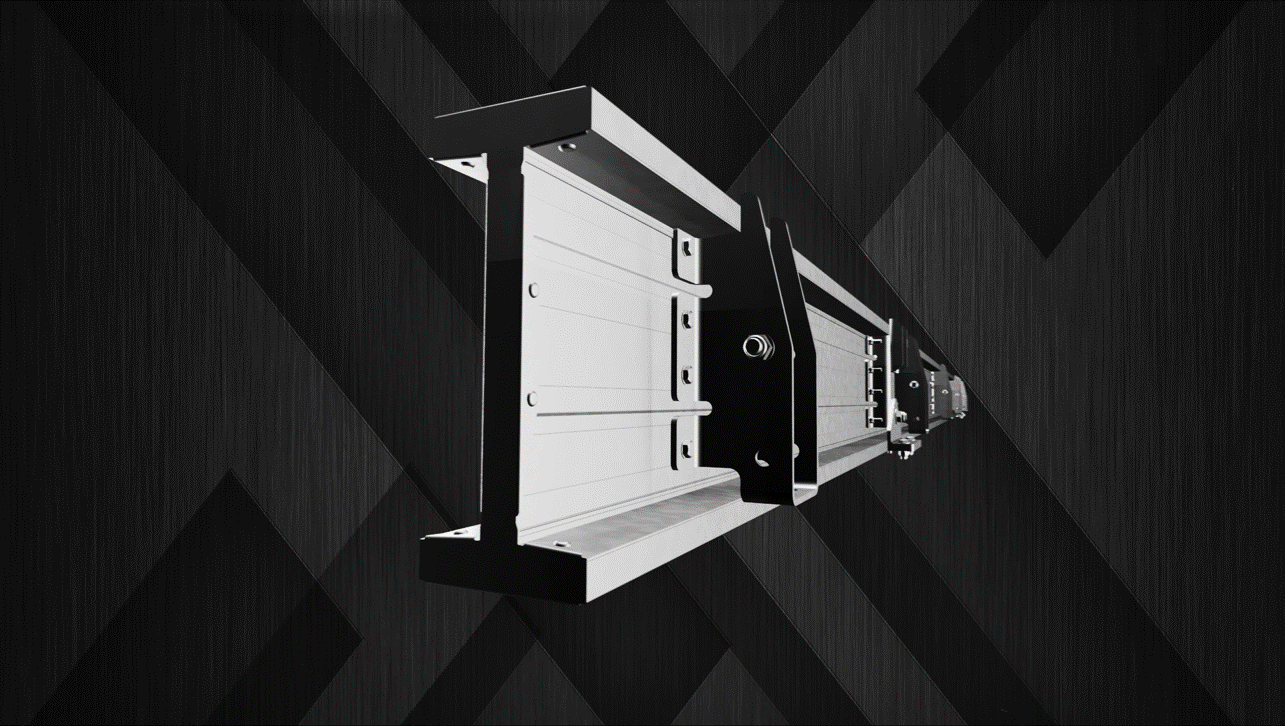

The Monkeytoe X BEAM is a key to a revolutionary lightweight configurable aluminium support beam system that is part of our modular, X BEAM platform system in New Zealand. This system excels in rooftop mounting and other long span high load applications where typically steel ‘I Beams’ are used.

Up to 65% Lighter than steel equivalent, Less loading on supporting structure. No surface coating requirements for corrosion protection.

For superior acoustic performance compared with similar products.

Handrails, louvres and Hushmonkey acoustic screening systems. Configured to specific site requirements.

Pre-engineered beam system. Can be assembled on ground and lifted into place

Fast install using more offsite, pre assembled packages due to the light weight, high strength beam. No hot work/welding required.

Pre-engineered connections to portal frames.

The Xbeam can enable the building structure to be lighter given that the weight reduction is substantial. Where the traditional 10m x 10m platform might weigh up to 10,000kg, the Xbeam is 3500kg.

The drastic reduction of the number of sub-trades working above the roof reduces the risk of damage to the roof.

The Monkeytoe Xbeam allows the roofer to complete his back flashings without the frustration of working around the completed platform which simplifies the flashing installation role.

By enabling assembly of the platform at ground level, you open up the opportunity to have the HVAC installer to begin his work before the roof is finished, thus removing one more critical path item from your timeline.

There is no requirement for the platform deck to be assembled above the roof and by assembling the screening at ground level the requirement to use mobile scaffold or ladders is eliminated.

The Xbeam means the roofer can install his roof without the obstruction of the platform. They’re simply flashing around the verticals and can complete their project prior to the platform actually being delivered to site.

This means the roofer can be more effective, and it enables a cleaner sign off by the roofer prior to other trades accessing the roof.

Galvanizing generally does not come with a warranty. When it does it’s between 2-5 years. Xbeam warrants up to 25 years.

A traditional platform with decking, handrails, acoustic treatment and screening can involve up to 4 sub trades to complete. The Monkeytoe package covers the entire process and enables ground level or off site assembly.

Monkeytoe has completed the design for the Xbeam, the screening systems and the Acoustic material. These have all undergone theoretical and practical testing to ensure the results are relevant when installed at roof level.

Using Monkeytoe Xbeam ensures more consistency, greater flexibility and less design time.

We sat down with Tane from Pacific Environments Architects to see how the new XBEAM system is a game changer in his practice.

A discussion with Ric from Calibre Consulting enlightened us as to how the new XBEAM system really is a no-brainer for a Structural Engineer.

After speaking with Josh from Laurenson Building Company, we understood the true value of using the new XBEAM system for his company.

Learn how this revolutionary product evolved from an idea through prototyping and finally finished product in use on sites in New Zealand and Australia.

T: 0800 454 808 (within NZ)

T: +64 6 272 8708

PO Box 360,

Hawera

Taranaki 4640

A direct comparison demonstrating the benefits of using a structural platform.

| MonkeyToe | Traditional | |

|---|---|---|

| WEIGHT PER M2 |

30 - 40kg |

80 - 90kg |

| SCREENS / HANDRAILS / ACOUSTICS |

Single Monkeytoe Package |

Up to 4 subbie packages |

| CRANE LIFTS REQUIRED |

1 - 2 lifts for the completed platform and units |

3-6 lifts including platform structure, platform decking, screening material, units |

| LOAD CAPACITY |

2.5kpa and 5kpa |

2.5kpa and 5kpa |

| AVERAGE NUMBER OF MAN HOURS TO INSTALL ABOVE THE ROOF PER SQUARE METER OF PLATFORM |

3-7 mins |

15-25 mins |

| CONCEPT DESIGN |

Monkeytoe has a well-equipped in-house design and engineering team who generate concept designs which can quickly evolve into full solution drawing sets throughout the design process. |

The initial concepts can be too high level and enable core considerations to be missed. |

| DETAILED DESIGN |

Monkeytoe can generate these quickly using our in-house design and engineering team. The co-ordination with HVAC, the Architect and Monkeytoe is simple and semi automated which enables quick and accurate design changes to suit. This requires a simple sign off from our engineer post configuration and the process enables a same day response time. |

This requires the manual co-ordination of HVAC, Structural engineering, Architectural and the fabricators to deliver a quality plan which in some cases can result in up to 6 iterations of the design and chew up unplanned resource at a critical time on the project. |

| DESIGN CHANGES |

As the entire system is designed for flexibility, changes to the structural support members can be quickly and efficiently integrated into the manufacture drawings. These last minute changes are often what causes unnecessary and costly manufacture delays. |

Workshop drawings require sign off weeks in advance of manufacture and often the HVAc layouts are changing right up till the last moment. The lack of flexibility in last minute design is often a source of project frustration. |

| INSTALLATION |

The system can be fully assembled at ground level and lifted into place with screens, handrails and decking completed. Because the system is light weight and rigid the risk of screen damage is minimal. |

Whilst these can be configured at ground level, generally it’s not practical to install screening prior to the lift due to the weight involved and the potential to twist and damage the screening during the lift. |

T: 0800 454 808 (within NZ)

T: +64 6 272 8708

PO Box 360,

Hawera

Taranaki 4640

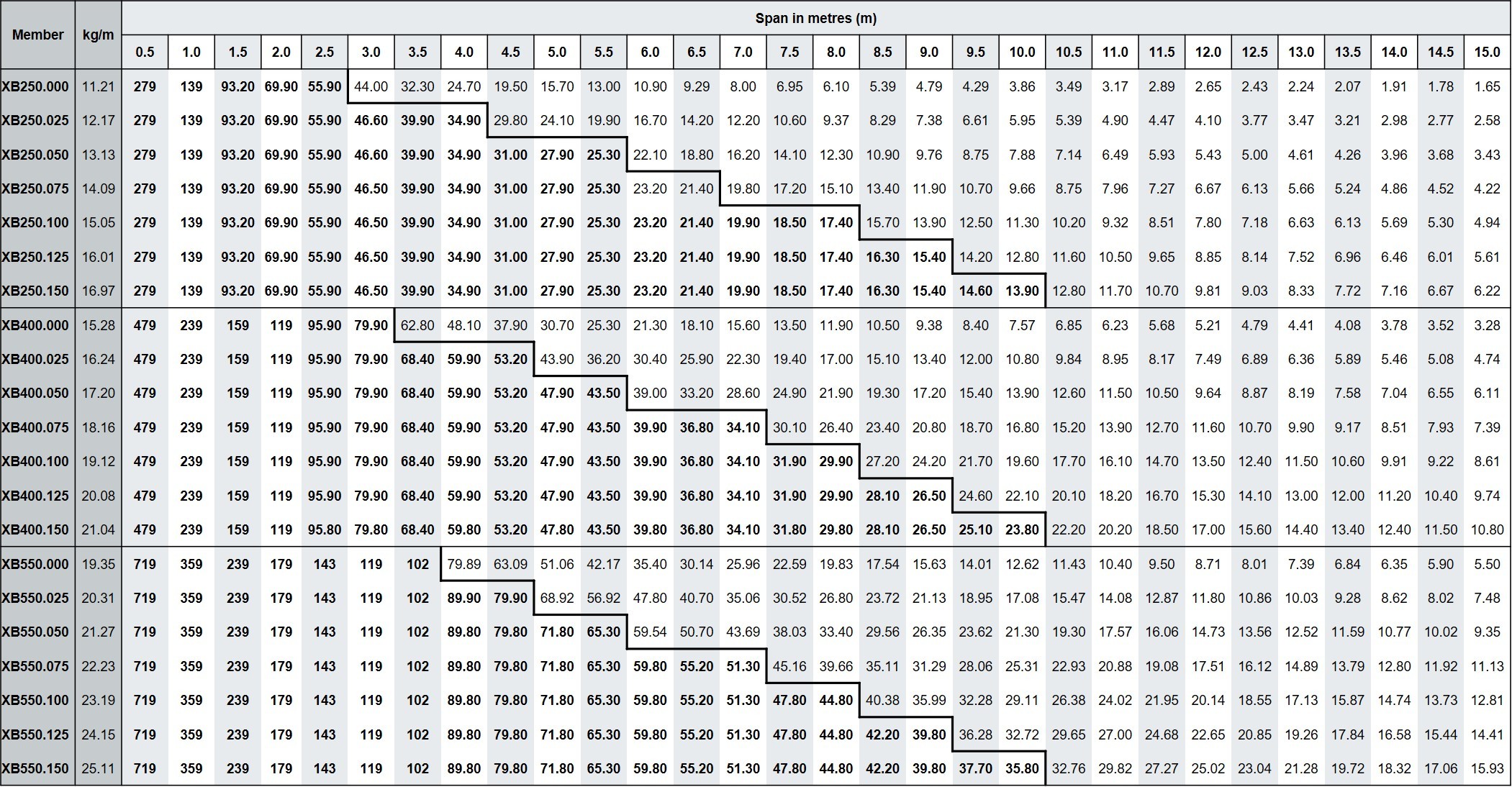

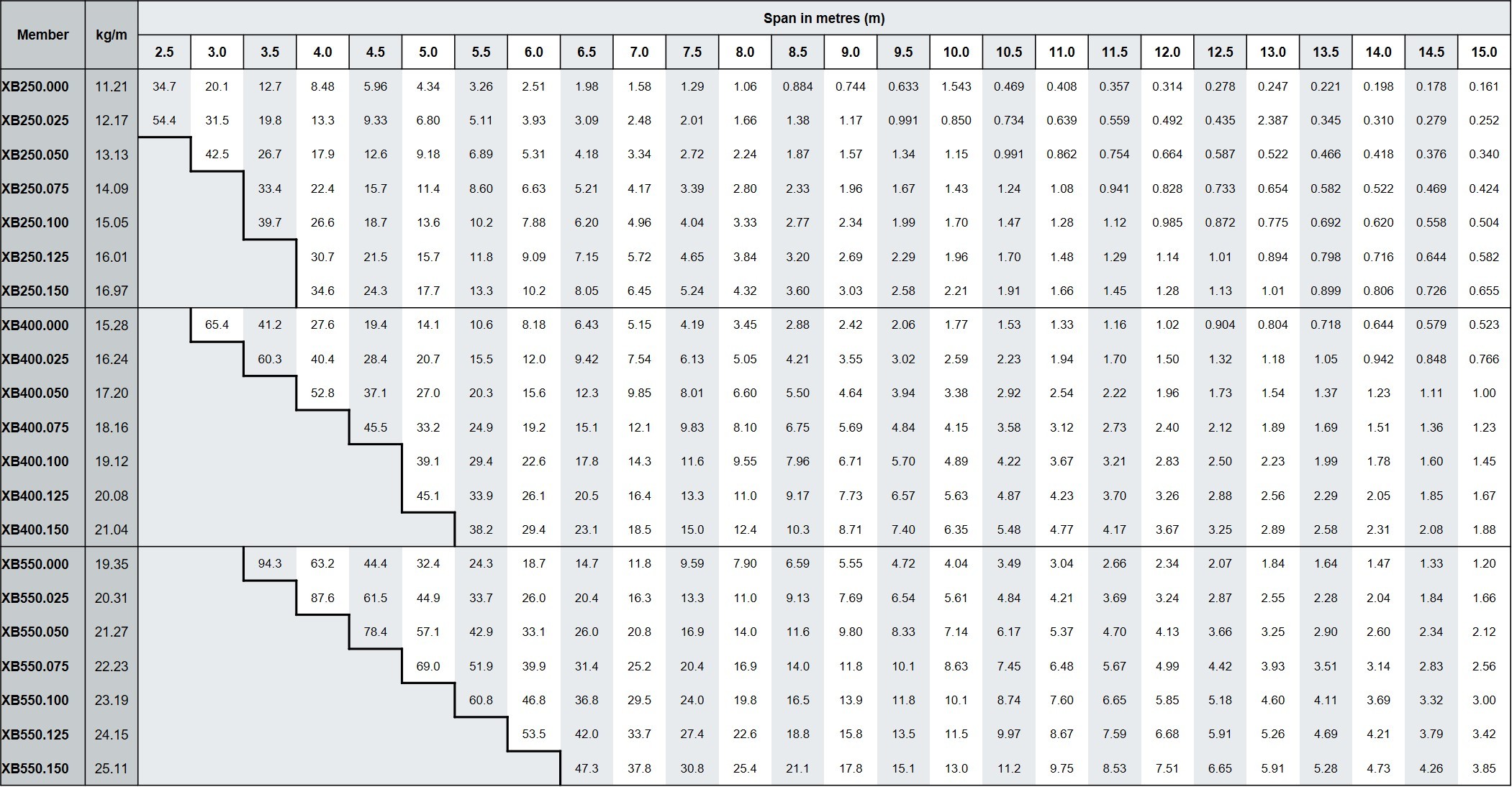

Uniformly distributed design load capacity (kN/M) with simply supported conditions + full lateral restraint.

(*Bold line indicates difference between shear and bending failure mode.)

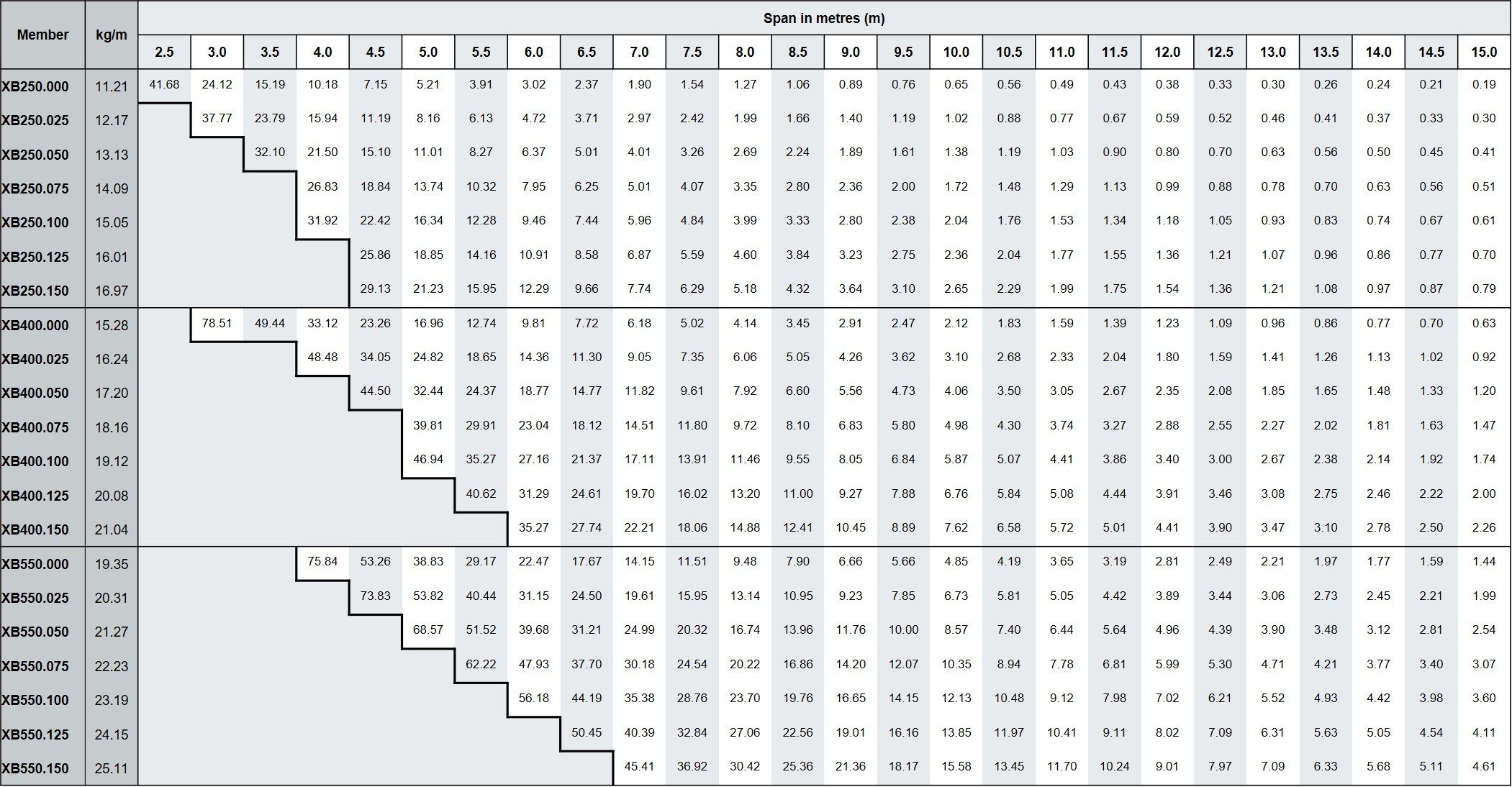

Uniformly distributed design load capacity (kN/M) for L/250 deflection. Simply supported conditions + full lateral restraint.

(*Values under bold line do not reach deflection limit prior to shear/bending failure.)

Uniformly distributed design load capacity (kN/M) for L/300 deflection. Simply supported conditions + full lateral restraint.

(*Values under bold line do not reach deflection limit prior to shear/bending failure.)

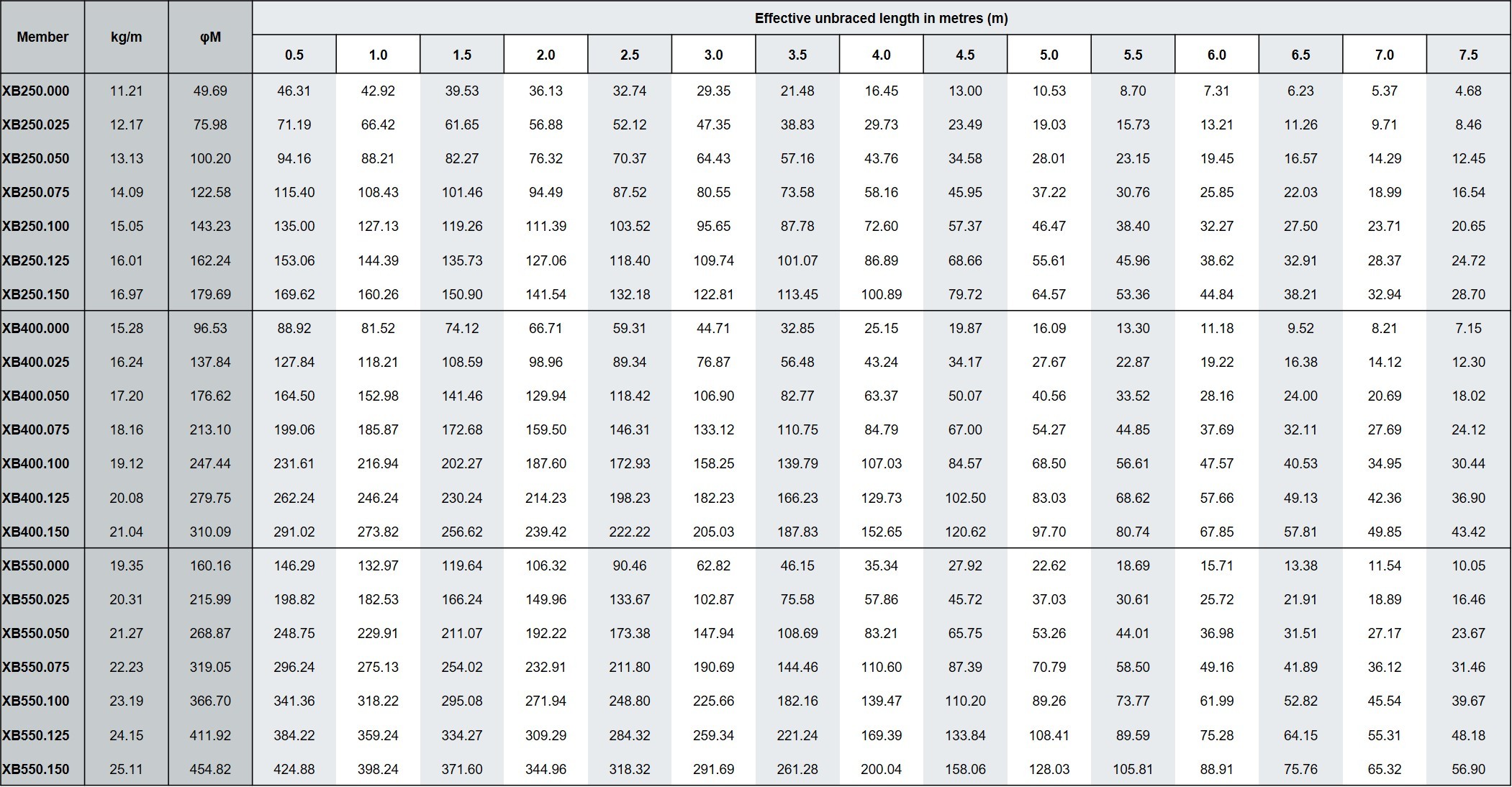

Design moment capacity (kN/M) without lateral restraint.

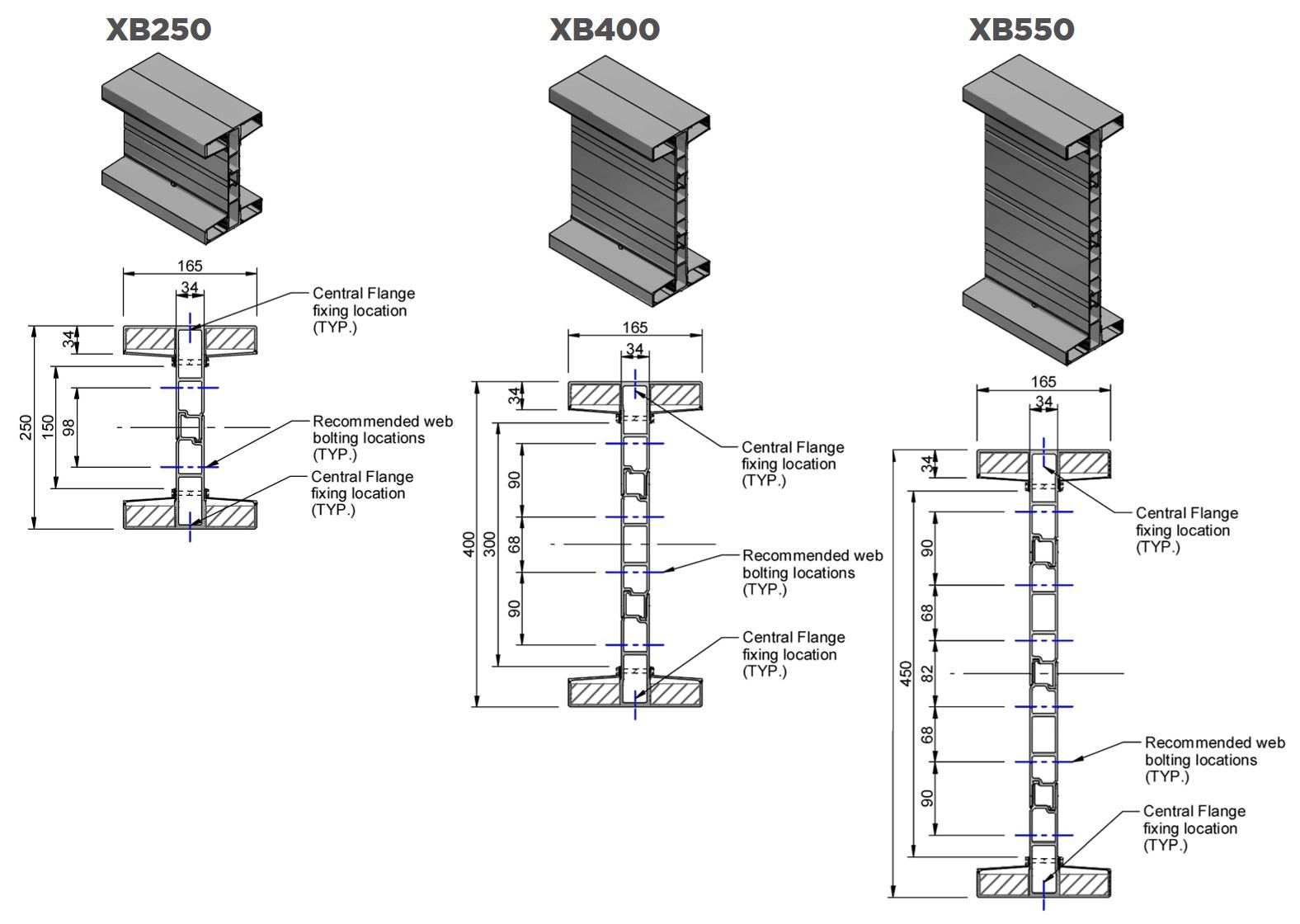

The Xbeam is highly configurable whereby the carbon fibre quantities can be altered depending on loading requirements. There are currently three main beam height options.

This system is designed in accordance with Aluminium Structures, Part 1: Limit State Design AS/NZS 1664.1 Standards Australia / New Zealand NZS/AS 1657.

Fully documented third party testing to ensure compliance to the building code. These included deflection, horizontal, load and temperature and durability.

Downloads

T: 0800 454 808 (within NZ)

T: +64 6 272 8708

PO Box 360,

Hawera

Taranaki 4640

T: 0800 454 808 (within NZ)

T: +64 6 272 8708

PO Box 360,

Hawera

Taranaki 4640