Check out what's been happening at Monkeytoe in April in our latest monthly news feature.

A note from Budd

Hi everyone,

It’s been a busy month here at Monkeytoe. Both sides of the Tasman are going full tilt, which means we’re seeing our solutions flying out the door (and could mean you’ll find a Golden Ticket in your hands – read on for more of that!).

In our industry, the status quo reinforces concrete and steel – but we’re all about flipping the script on what people expect and instead offering something revolutionary. That’s long underpinned our work with aluminium, of course, and it’s also led us to create some really innovative solutions like the XBEAM.

Looking back and moving forward has also seen timber products and natural surfaces reappear in the industry – something our R&D guru Glen Thomas explores in relation to cross-laminated timber (CLT) and the benefits to not just prefabrication, but also to the look and feel of our spaces.

This month we revisited Lyttleton Port to talk to Alistair Boyce about working together on an innovative access solution, so read on to hear more about that…

Cheers,

Budd Prestidge, General Manager

More from Lyttleton Port Alistair Boyce – video interview with Lyttleton Port

We managed to catch Lyttleton Port’s Head of Engineering, Projects and Asset Management, Alistair Boyce, for a few choice words on our work creating a new access solution.

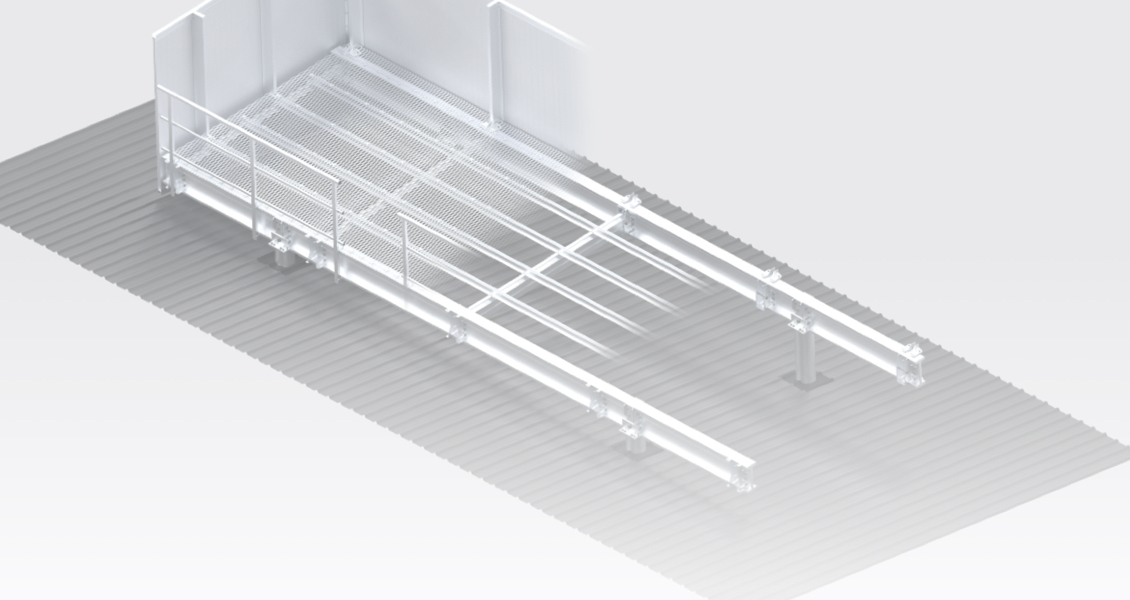

Alistair looks after the development of new infrastructure and the maintenance of existing assets – so he was pretty invested in a new access solution that would enable them to handle an additional 70,000 containers that would be heading their way thanks to a new contract.

They had a very short timeframe – just five weeks – to convert a pavement block into an area that could support a large proportion of refrigerated units. They also needed to provide safe and quick access to the three-high stack to maintain the containers and connect the refrigerated units to power and keep the goods fresh.

Have you got a Golden Ticket?

Will you be dancing for joy like Grandpa Joe?

From today onwards, it’ll pay to check your Monkeytoe boxes, because we’ll be placing Monkeytoe Golden Tickets in random standard mount boxes right before they’ve left our factories.

Up for grabs is a special gift from Monkeytoe. If you’ve receive a Golden Ticket, make sure you follow the instructions on the card to claim your prize. Happy hunting!

Get yourself to Moggill Village

With 6100sqm of retail – including a staggering 3500sqm Coles supermarket – Moggill in West Brisbane has recently welcomed its latest shopping centre. The aptly named “Moggill Village” complex is the first in the suburb in almost 50 years, and should bring in 200+ jobs to this booming part of the city.

It’s also been a chance for us to showcase some of our newest solutions for the good people at Consolidated Properties Group (in conjunction with Newground Capital Partners, who developed this site).

We provided one large platform for the Coles supermarket – an incredible 23x9m platform over the ridge of the roof – along with 2.4m high Hushmonkey acoustic screening for three of the sides to minimise noise from their powerful roof-mounted HVAC units.

We also had the chance to provide three other secondary platforms for mounting of tenants’ equipment, with Hushmonkey panels to all sides.

And because we love locally-made, the Moggill Village platforms and Monkeytoe solutions – like all Australian projects – were all designed and engineered in Australia to meet our unique demands, then manufactured from Australian marine-grade aluminium at our Melbourne factory.

The complex is already buzzing with activity – so get yourself over there soon and check out what’s going on at Moggill Village!

Glen Thomas on prefabs, CLT construction, and DFMA

This month, we brought back Glen Thomas of our Research and Development division to talk about the rising trend of CLT construction – and how he sees it taking over the Australia and New Zealand building markets.

The world’s going prefab. There are a few factors at play, not least the fact that there’s increasing pressure for faster installs on site, making construction periods shorter (therefore cheaper) and to get tenants in sooner (to start generating revenue).

We’re also seeing a greater uptake across the architectural and design space for more eco-friendly and longer-lasting projects – ones that look good as well as being good for people and the environment. That’s why the industry is shifting quietly towards CLT as the 21st century solution.

CLT means ‘cross-laminated timber’, and no, that doesn’t mean plywood. The design is similar, however: layers of timber adhered perpendicular to each other. While ply is typically made from thin layers (peeled with a rotary lathe), CLT uses solid-sawn timber for a thicker, more durable and more attractive product.

CLT and prefabrication reduce on-site labour, use less energy in manufacture, and reduce project timeframes. CLT’s lighter than steel, faster to fabricate, easier to machine, and faster to install on site. CLT and prefab construction uses renewable, locally-sourced materials (like Australia and New Zealand’s great FSC forests, which also support our primary industries) and actively helps reduce our climate impact. While concrete releases CO2 during curing, timber draws it out throughout its growing life.

It does take a completely different design process and mindset, however – something that’s untraditional in a modern sense (where concrete and steel are the status quo), but has a much longer legacy, especially in countries like Japan and across Scandinavia. A recent report found that a seven-storey building in Sydney with CLT-led design could be 12% cheaper than the equivalent made from exclusively concrete and steel components. The report also found that, while the timber itself was about 40% more expensive than concrete columns, the different approach to design actually resulted in a saving of 92% on components of the design.

Mechanical services are also becoming increasingly modular and prefabricated, which means we’ll continue to see plant rooms shift outside onto otherwise unused roofing space (rather than take up good real estate indoors). The best place to put it is on a platform where it’s safer, faster to prefab, and easier to maintain. If you’ve designed for CLT, though, you’ll need a light and strong platform.

All of this plays to our strengths and the benefits of our XBEAM, of course. As design for manufacture and assembly (DFMA) increasingly forms the foundation of 21st century construction, we’ll continue to see innovations that work with the latest trends – and that allow for safe and reliable retrofitting existing buildings.

Mornings with Monkeytoe

Surrounding the innovative Xbeam is a wealth of interest and intrigue, so join us online for a series of Morning livestreamed events, as industry professionals chat about Xbeam by Monkeytoe!

Learn about the background, discover the hidden details, get insights behind two key completed projects, and understand how Xbeam can be your next project’s lifesaver!

All four episodes (the first of which has already been) are around 30 mins long and run over four weeks (one morning each week). An enlightening, informative series that is not to be missed, and let’s get it straight – it’s not another cliched webinar, but a dangerously riveting livestream!

The next episode will take place on Friday 7th May. Be sure not to miss out and register here to receive your invitation to attend this event hosted on Zoom.