Check out what's been happening at Monkeytoe in October in our latest monthly news feature.

A note from Budd

Hi everyone,

With a busy industry and more projects being planned than ever, we’re finding ourselves working with good sorts all across the country.

Just as well we’ve got a solution to fit every need – and the team working tirelessly behind the scenes to innovate, test, and take Monkeytoe further than ever before.

In this month’s update, we spoke with testing specialist and all-round clever sort Logan Klenner, ‘the father of the XBEAM’, about what it means to put our products through their paces before they make it to you – and why we’re investing so much in our testing.

We’re also looking at a project for Palmerston North Hospital, supporting the good sorts at the newly-formed Te Paepae o Aotea, and welcoming Jessie Webb to the Monkeytoe team.

There’s plenty to check out in our latest update – so dive in and see how we’ve been busy this October.

Cheers,

Budd

Monkeytoe testing with Logan Klenner

We had a chat with Development Manager Logan Klenner, who’s leading the charge when it comes to innovation and product testing here at Monkeytoe.

Over the last 12 to 18 months, we’ve invested a lot of time and resources into our testing capabilities, equipment, and our data-gathering capabilities. A few years ago, we started out with a 2-tonne load cell to test the capacity of our products. Then we got a 10-tonne unit. Now, we’re at 50 tonnes. We’ve upped our testing capacity and included new digital data acquisition equipment for strain gauges, load cells & thermocouples etc, because the scale of what we do has grown, and we’re getting into bigger, more serious structures. That means we’ve had to get more data and better insights as to how our products perform.

There’s only so much you can do in theory or on computers. We have computer-aided modelling, but even the very expensive tools that NASA uses (like FEMCI – Finite Element Modelling Continuous Improvement) only provide so much data about how a design will perform over its lifetime. You can load any design into a modelling system, and it’ll give you hot spots – usually where it should fail first. But the chain of events that follows once that failure starts can be unpredictable.

Testing means we get to see beyond that first stress point and see whether a design will fail quickly (which means it needs to be designed with much higher safety margins, or have predictable failure modes introduced by design), or slowly and predictably (which means we can put measures in place to predict and maintain before it becomes unsafe). You can design in connection types that would give indications of failure long before they happen – the canaries in the coal mine, as it were.

While the basic shapes like I-beams, parallel flange channels, rectangular hollow sections etc. are well understood and the mathematics behind these are established, the complex shapes we can extrude in aluminium are more complex to predict, and so need more testing. For example, we designed some lintel beam extrusions, and the theoretical numbers suggested it would fail between 4 and 8 tonnes in a given 4-point bend test (depending on the calculations used from the Aluminium design code AS/NZS 1664). That’s a huge range, and not one that fills people with confidence or allows us to design with efficiency. The actual failure load from testing was around 9.5 tonnes, which meant we now had a reliable figure to work with, and a better understanding of the initial failure mode and the roll-on events following that failure initiation.

We’re continuing to invest in our testing capabilities as we expand into new industries and go further than ever before. And we want to be transparent about what we’re doing. Aluminium solutions aren’t as well understood as steel, which means we’ve got some education to do to prove that they’re the best answer for lighter, smarter solutions for the 21st century.

Palmerston North Hospital

The Palmerston North Hospital project has been a massive, much-needed undertaking. Part Covid ward, part ED ward, the latest additions have rolled out in stages over the last 15 months or so.

Codenamed SPIRE, the projects have been part of several major capital works planned for the hospital that services the central North Island.

But, like all great plans, sometimes things go awry. The main contractor ran into complications regarding how to house all the infrastructural services in the limited roof space safely and securely. Fortunately, we were on hand to develop a turnkey solution.

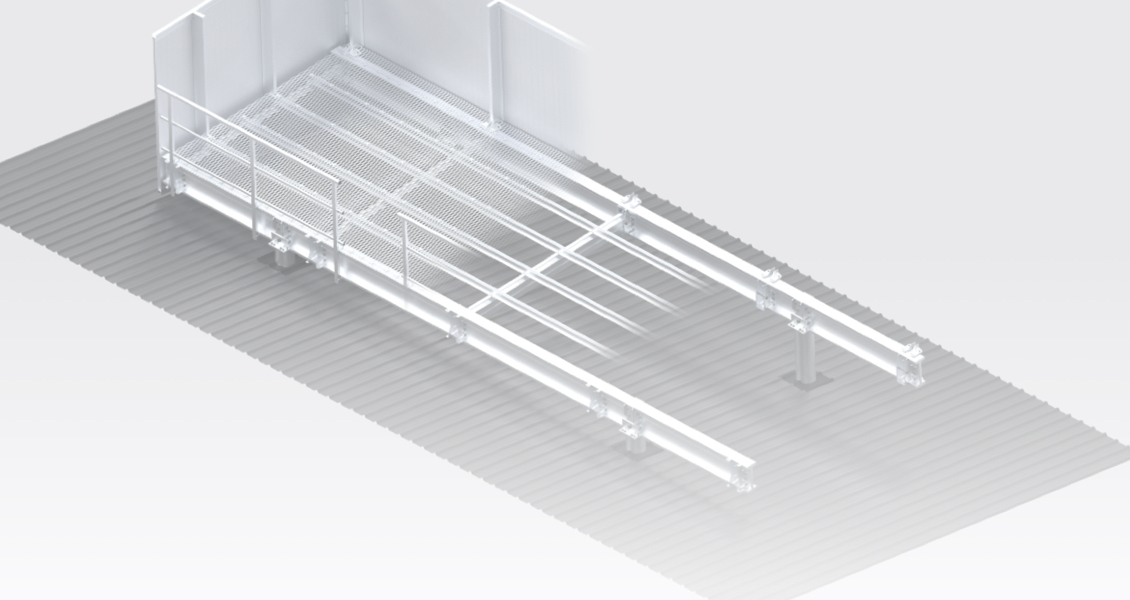

We provided an external access stair to run from the ground floor. A plant platform to house air conditioning units also became a walkway inside the building – which was all encased in the roof space with a suspended ceiling to hide it from view. We were able to provide support for cable trays, electrical ducting, plumbing and air conditioning with a marine-grade solution that’s a third of the weight of steel, all added late to the total project and done without compromising the existing structure or requiring significant design changes.

With project completion scheduled for December 2022, we’re excited that Palmerston North Hospital will be able to better help its people safely.

Supporting Te Paepae o Aotea

You’ve got to support your locals. Taranaki has come together to support Hawera Intermediate School since a fire destroyed three-quarters of their buildings back in 2015, with temporary buildings and support services. And we’ve kept an eye on how things are going too, since they’re only ten minutes down the road from our head office.

Sadly the decision was made earlier this year to close the Intermediate at the end of 2022. But this has also opened a new door: the creation of Te Paepae o Aotea. Combining Hawera Intermediate and High Schools, Te Paepae o Aotea (meaning We are all on the learning journey of Aotea, as the people of South Taranaki, realising our full potential) will cater for years 7-13 in the area and take students further along their cultural and educational journeys.

Many members of the Monkeytoe team have kids who went to Hawera Intermediate, or know someone who did. So we wanted to send some love in our own small way to this school that’s important to the community – and that’s what we did, with an armload of ginger beer and nuts to share with the new Te Paepae o Aotea. And it started a conversation about turning our engineering skills to creating aluminium basketball hoops for the kids (and the big kids too)!

Welcoming Jessie Webb to the Monkeytoe team

As Sales Assistant and Customer Service Support, Jessie Webb is a name that most of you will encounter while you work with Monkeytoe in the future.

Having worked with the likes of Fonterra, Jessie was ready for a new challenge – so she joined the team in September on a mission to help us deliver great customer service. She’s all about supporting our clients to make the right decision about their access needs and making sure that you know what kinds of solutions we have on offer. She’s also in charge of gifts – and the mastermind behind the donation to Te Paepae o Aotea.

A keen baker, Jessie’s settling into the office well, bringing a generous spirit – and even showing some of the team how to make fry bread in her second week!