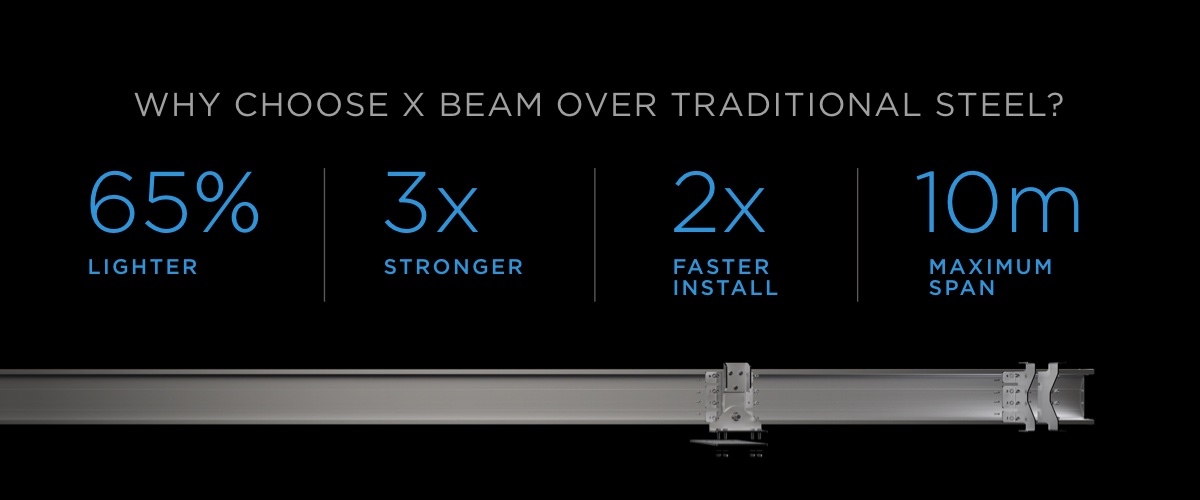

The Monkeytoe XBeam is faster to install, stronger and lighter than standard structural steel alternatives. It’s capable of spanning greater distances, deflecting more noise and supporting greater weights. It really is the beam that’s raising the bar. What makes the Monkeytoe XBeam possible is the combination of marine-grade high tensile T6 aluminium with the unparalleled directional strength of carbon fibre reinforcement to produce a beam that’s up to 65% lighter than steel. It can also span more than 10 metres while supporting greater loads than traditional steel beams can. This beam is almost twice as strong as steel, yet a fraction of the weight.

Greater than the sum of its parts

“We spent about three years talking to builders, designers and engineers, trying to work out what benefits we needed to offer,” says Budd Prestidge, our General Manager who has been leading the development of the XBeam.

“As we worked through the different options, the best one came out to be carbon with aluminium. Aluminium can have a lot of flex in it, depending on the configuration. Carbon is very rigid, strong, and light. By combining the two, you get a very strong, very rigid beam.”

We’ve been singing the praises of aluminium for some time. It’s lighter than steel, it corrodes 100x slower, and it has a higher strength-to-weight ratio, so it goes where steel can’t. More recently, we talked about the power of reinforced composites in our ebook “Bigger, Taller, Stronger: Realising the Potential of Carbon Fibre”. Carbon fibre’s engineered directional strength and exceptional strength-to-weight ratio make it popular in the aerospace industry and in high-performance cars.

By combining these technologies, we’ve created a beam – and a platform system – that’s greater than the sum of its parts.

Realising the potential

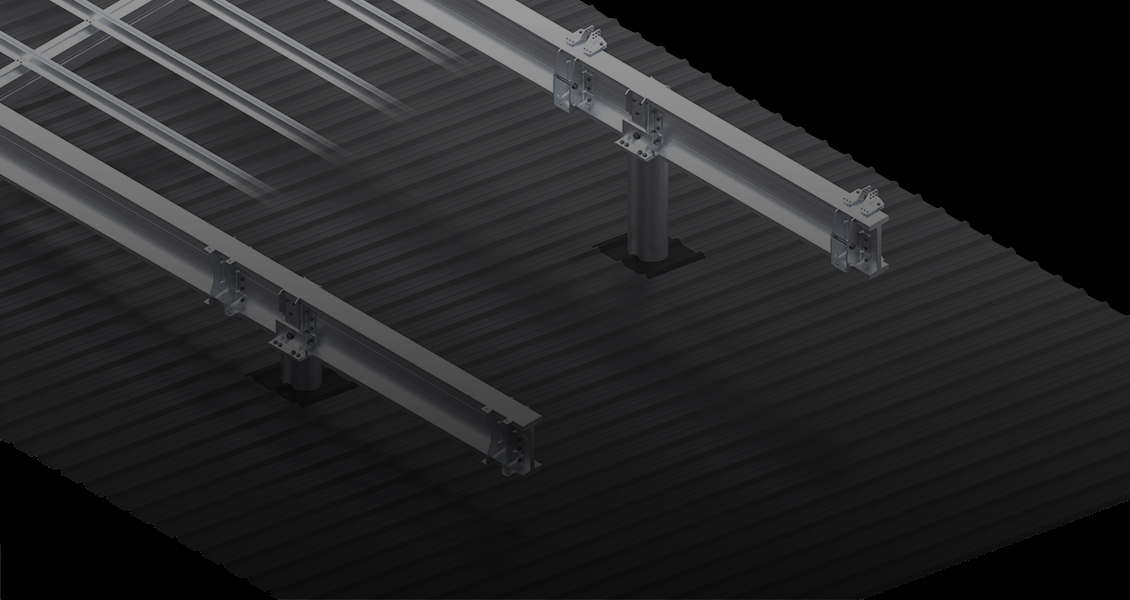

With superior strength, a lighter weight and a greater span potential than steel, the XBeam offers a new opportunity to think about how designers and architects use space. The first use? A new kind of rooftop platform.

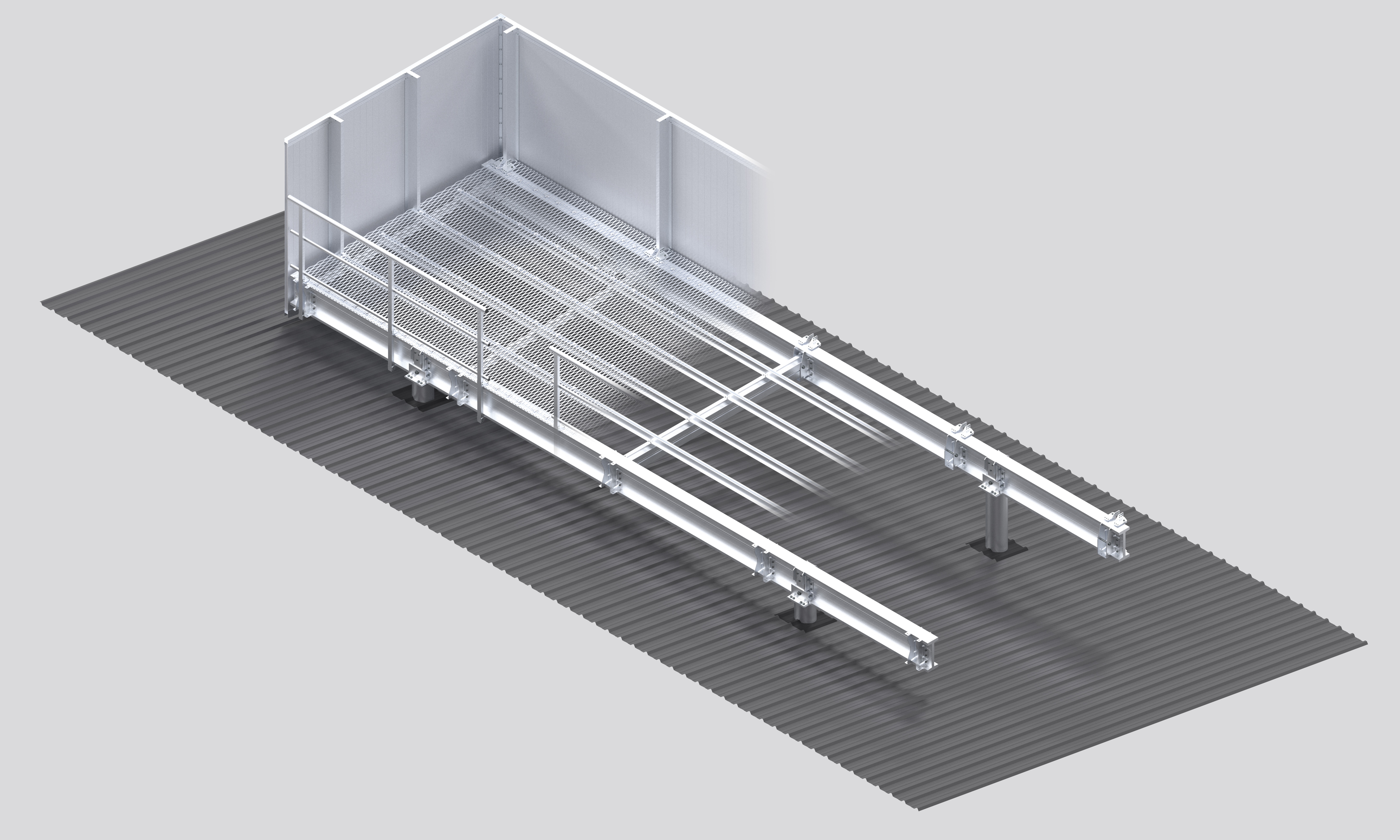

“What we realised was that, with a rooftop plant platform, there are three key issues,” says Budd. “The flexibility in design, and the weight of the platform – which can be two times, three times the weight of the equipment it’s supporting. But the biggest issue is the hundreds, sometimes thousands, of man-hours performed at height.”

Our XBeam platforms have been designed from the ground up to be reconfigurable up to the last minute and, most importantly, able to be assembled on the ground. That reduces the risk of working at height, and removes the issues between structural steel work and the other trades required. When it’s all assembled, it’s simply a matter of lifting the platform and all the HVAC units onto the prepared rooftop – often with a single crane.

“There’s a lot of flexibility with the XBeam,” says Budd. “Any situation where weight is a consideration, we can change the amount of carbon inside that beam.”

Changing architecture and building

The XBeam’s potential to change how we think about spaces and construction has huge ramifications for architects and builders, and structural engineers like Calibre’s Ric Low. Ric works largely on warehouses, apartments and high-rise offices, so he understands better than most how loads affect large spaces.

“Whenever you have a plant room on your roof, you would need quite big members that would go up to that roof level as well. Especially with apartment blocks, that would mean big columns poking through liveable spaces – and no one really wants to see that.”

The appeal of the XBeam? “Good cost, and how it achieves a superior strength-to-weight ratio,” he says. The XBeam can open up spaces by reducing the number of members required, without sacrificing any strength. That means more usable working or living space to take advantage of.

Not only does the lighter weight at higher levels open up space, it also reduces the architectural challenges of wind or earthquake loading. For Josh Laurenson, Director of Laurenson Building Co. in Auckland, the XBeam also means faster install and fit-out on site. And when time is money, working with efficiency matters.

Since a Monkeytoe XBeam platform can show up and be lifted onto a roof, you don’t have “contractors coming in, getting the materials on the roof, cutting them to size, doing hot works, and risking damaging the existing building that’s already 95 per cent complete,” says Josh.

Lower risks on site mean a safer and faster fit-out. “If we have less people to deal with, and products showing up finished,” says Josh, “it’s going to save us a lot in the long run.”

The revolution is now

Faster, lighter and stronger, we’re proud to say that the XBeam is the beam that’s raising the bar for what’s possible in the construction and design industries. We’ve started with the XBeam and HVAC platforms, but the potential with this adaptable and tailored technology across the industry is huge. Watch this space.